Maintaining a balance between creating high quality dairy ingredients while maintaining a low production cost can be challenging. KSS’ Sani-Pro® line of membrane products utilize a blister resistant design and crossflow filtration technology to improve energy efficiency, reduce operating costs, increase productivity and decrease contamination risk. Sani-Pro membranes are constructed to tolerate harsh cleaning requirements extending their operating life and optimizing every step of dairy membrane processing.

If you are concentrating, clarifying, or demineralizing whey protein, our protein-separation processes can help you reduce operating expenses and boost yield. We also offer complete evaporation, crystallization, spray drying systems, and powder handling & packaging systems

Ideal for:

CONCENTRATION

Our RO, NF, & UF membranes are used to concentrate and fractionate many different valuable materials used in the food, dairy, beverage and pharmaceutical industries. KSS wide product offering allows us to select the most suitable product for each application.

DEMINERALIZATION

KSS’ membranes and ion exchange systems are utilized to purify a wide variety of food, dairy, beverage and pharmaceutical products to provide high quality and long shelf life products.

SPRAY DRYING or Crystallization

Drying capabilities designed specifically to process a full-range of dairy products at the lowest capital and operating costs in the industry

CLARIFICATION

KSS’ UF and MF membranes are used to produce crystal clear permeates that are used in food and beverage production, pharmaceutical manufacturing and ultrapure water processes.

EVAPORATION

Our MVR and TVR evaporator systems are designed with maximum flexibility to concentrate a wide variety of dairy products to a high total solids percentage

Powder Handling

& Packaging

Packaging Systems and solutions is designed for sanitary applications, able to fill a wide variety of powders.

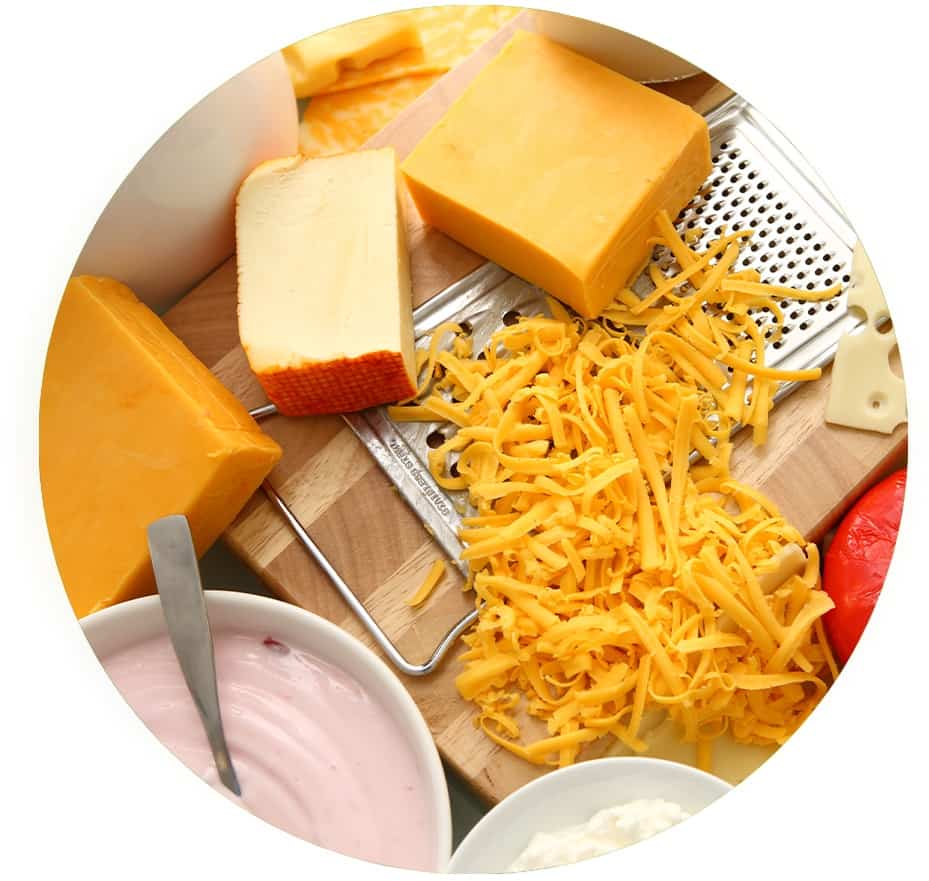

Our filtration and separation solutions for milk production and cheese production are exceptional at concentrating proteins for your milk products. In addition to membrane filtration, we offer complete evaporation, crystallization, spray drying systems, powder handling & packaging solutions, and a variety of cheese making equipment and solutions.

Ideal for:

CONCENTRATION

(CLARIFICATION)

KSS’ UF and MF membranes are used to produce crystal clear permeates that are used in food and beverage production, pharmaceutical manufacturing and ultrapure water processes.

EVAPORATION

Our MVR and TVR evaporator systems are designed with maximum flexibility to concentrate a wide variety of dairy products to a high total solids percentage

Cheese Making Technology

A variety of equipment and solutions to produce an array quality cheeses

DEMINERALIZATION

KSS’ membranes and ion exchange systems are utilized to purify a wide variety of food, dairy, beverage and pharmaceutical products to provide high quality and long shelf life products.

SPRAY DRYING OR

CRYSTALLIZATION

Drying capabilities designed specifically to process a full-range of dairy products at the lowest capital and operating costs in the industry

Powder Handling & Packaging

Packaging Systems and solutions is designed for sanitary applications, able to fill a wide variety of powders.

Our RO/NF membranes provide excellent performance in concentrating and demineralizing lactose streams. We offer complete evaporation, crystallization, spray drying systems, and powder handling & packaging solutions

CONCENTRATION

Our RO, NF, & UF membranes are used to concentrate and fractionate many different valuable materials used in the food, dairy, beverage and pharmaceutical industries. KSS wide product offering allows us to select the most suitable product for each application.

EVAPORATION

Our MVR and TVR evaporator systems are designed with maximum flexibility to concentrate a wide variety of dairy products to a high total solids percentage

Powder Handling & Packaging

Packaging Systems and solutions is designed for sanitary applications, able to fill a wide variety of powders.

DEMINERALIZATION

KSS’ membranes and ion exchange systems are utilized to purify a wide variety of food, dairy, beverage and pharmaceutical products to provide high quality and long shelf life products.

SPRAY DRYING OR

CRYSTALLIZATION

Drying capabilities designed specifically to process a full-range of dairy products at the lowest capital and operating costs in the industry

Our filtration and separation solutions for dairy processing wastewater treatment produce water for recovery and recycle back to the plant, or for direct discharge to drain. Depending on the technology selected, contaminants are either reduced sufficiently for discharge or significantly concentrated to substantially reduce hauling costs. Wastewaters from dairies are considered a challenge to treat, often containing high levels of suspended solids, FOG, BOD, and COD. Our systems and experience work to solve these treatment issues by not only applying the correct membrane configuration, but by combining these specialized membranes with over 50 years of KSS system design and direct installation experience on these waste streams.

Ideal for:

Wastewater Pretreatment

Dairy processing equipment wash, plant and facility cleaning, and CIP wastewater treatment for the separation of suspended solids, fats, BOD and COD solids, and other non-dischargeable contaminants.

Wastewater Reuse

Pretreated, TSS-free wastewaters can be further polished to remove dissolved solids from process water for recycle and reuse, reducing freshwater usage and end-of-pipe wastewater volume.

The KSS Causti-COR® Nanofiltration Membrane Systems offer a cost effective, environmentally friendly way to recover the expensive caustic solutions used to clean process equipment. Causti-COR systems utilize our patented SelRO® membranes to recover up to 95% of caustic for reuse by removing low molecular weight organic and inorganic contaminants.

Purification

KSS SelRO nanofiltration technology is utilized to remove most organic and inorganic contaminants from the caustic, resulting in a high quality recycled caustic and small waste stream, bringing cost saving benefits as well as improved process reliability.