Mining and metals refining are resource-intensive operations with high capital and operating expenses. KSS technology has been trusted by miners and refiners across the world to recover and recycle expensive process chemicals and metal byproducts, while ensuring a consistent and high-purity product output.

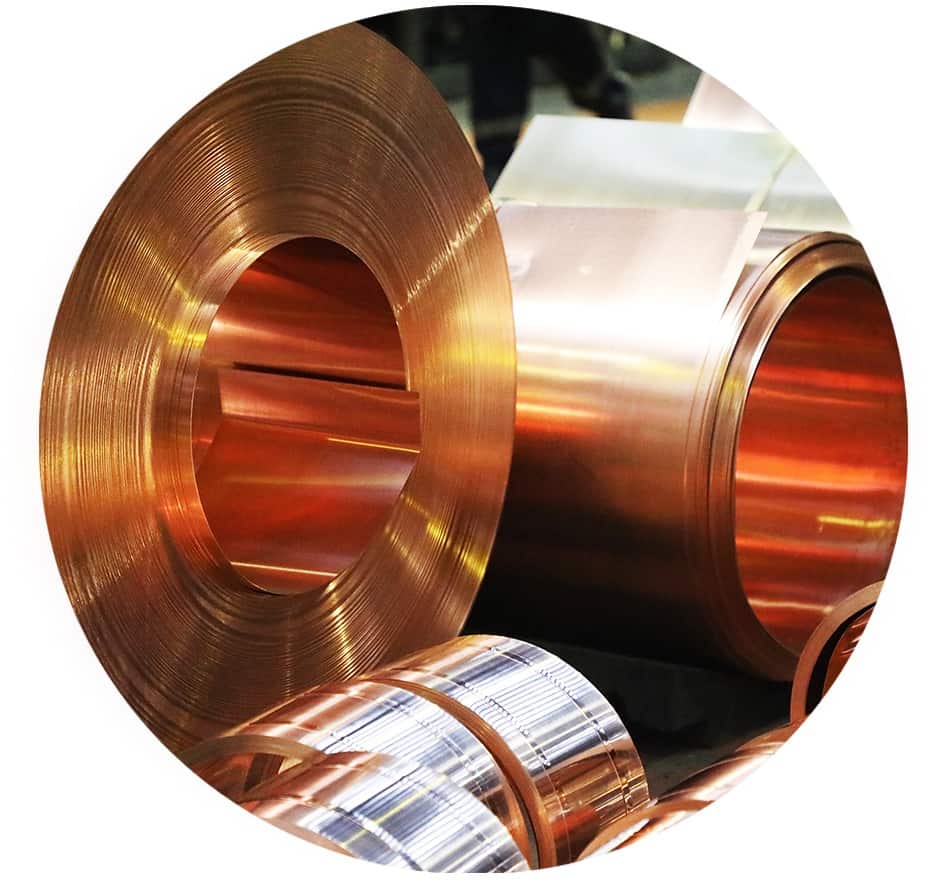

Electrorefining and electrowinning operations for high-purity copper production are susceptible to elevated levels of metal impurities and contaminated acid bleed streams. KSS technologies control impurity levels to ensure efficient production and consistent, high-purity product. Acid bleed streams are also purified and recycled back into the process to improve overall process economics.

Ideal for:

Acid Purification

Our systems remove contaminants present in the electrolyte bleed and recycle purified electrolyte. This allows operators to reduce contaminant levels, increase process efficiency, and save on acid purchases.

Nickel & Cobalt

Recovery

To further recover valuable nickel and cobalt salts, our nickel & cobalt recovery system can be employed to treat byproducts from the acid purification unit. High-purity nickel and cobalt salts are selectively separated using a specialized Eco-Tec Recoflo® ion exchange system.

Our filtration and separation solutions for heavy metal wastewater producing industries produce filtrate for recovery and recycle back to the plant, or for direct discharge to drain, while concentrating precipitated metals to meet discharge regulations and reduce hauling costs. Filtrate from membranes is substantially lower in concentration of metals and is significantly more consistent in quality versus conventional gravity separations, with the membrane itself being a true physical barrier. Wastewaters from these industries can be a challenge, but with the application of the correct membrane configurations and our installation experience your problem is solved.

Ideal for:

Wastewater Treatment

Heavy metals wastewater treatment by ultrafiltration is simply done via pH adjustment and hydroxide precipitation. Target pH for the membrane system’s operation depends on the particular metal’s pH solubility curve. Blends of different heavy metals call for a pH target that best precipitates all of the metals of interest. When simple hydroxide preciptation no longer attains discharge limits, now or when limits are tightened in the future, an easy switch from hydroxide to sulfide precipitation is all that is needed.

Our salt separation unit selectively removes chloride from sulfate and carbonate using a specialized ion exchange resin. The system operates on a loading step and elution step to effectively remove salt with a counter-current water wash, which removes chloride and returns resin to its original state.

Ideal for:

Chloride Removal