With its origin dating back to the mid-1930s, ion exchange technology is a proven method for removal of contaminants in process streams based on particle charge. A process fluid is pumped through a packed bed of charged polymeric beads that react with the ionic charges of the fluid, ultimately removing unwanted constituents. Originally developed with a phenolic-based resin for demineralization, many cationic and anionic polymer resins have been developed over the years to treat a variety of applications with contaminants or impurities such as nitrates, fluorides, sulfates, uranium, arsenic, tannins, etc. These developments have made it possible to apply this ion exchange technology to many processes in the food, beverage, and industrial markets.

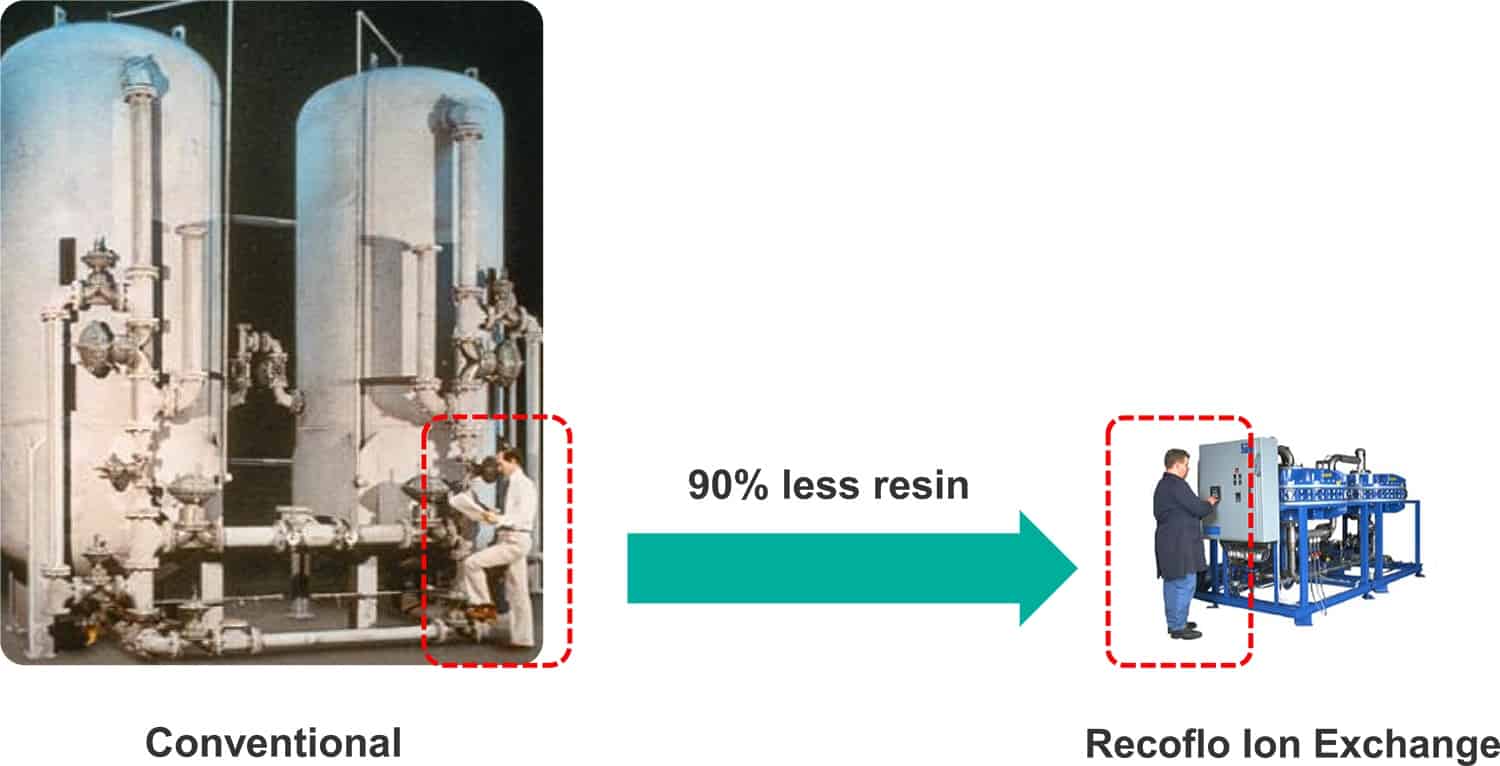

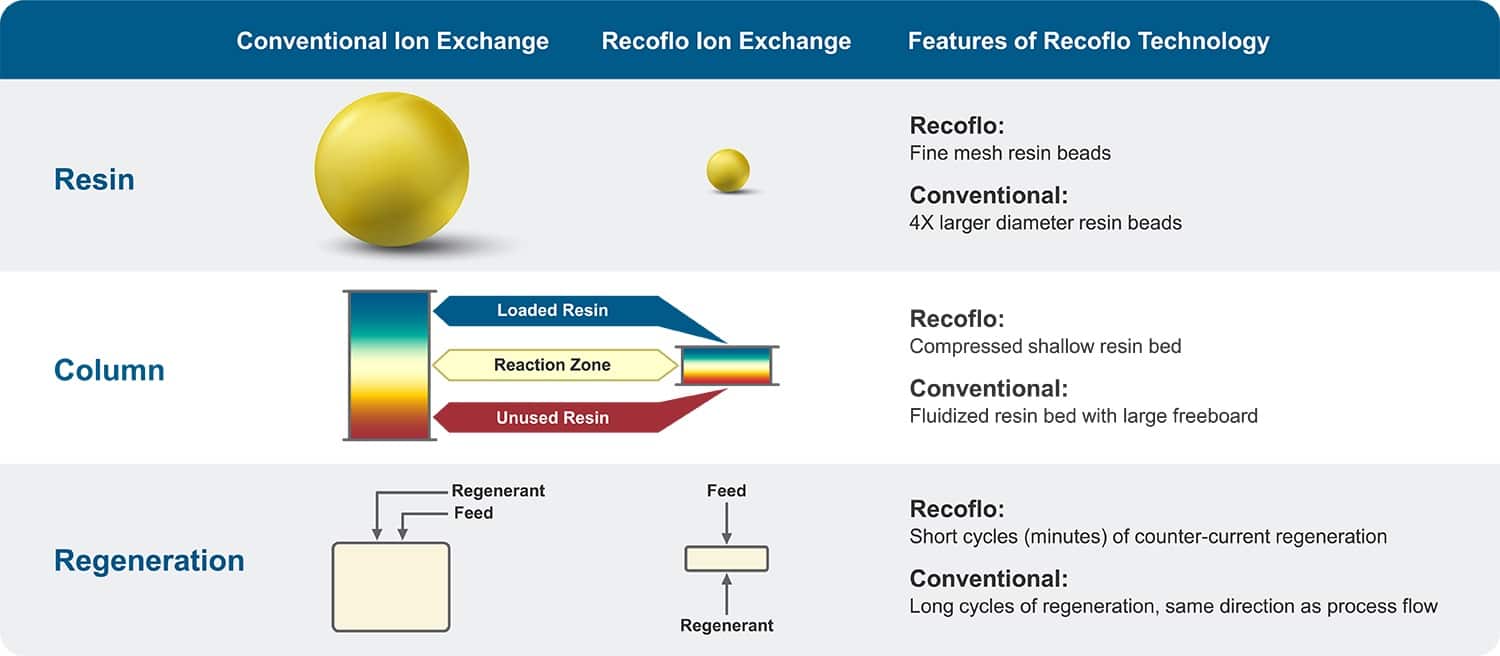

While leveraging this tried-and-true technology, Eco-Tec Recoflo® Ion Exchange offers a unique and innovative approach with significant benefits. Historically, conventional ion exchange has taken up a large footprint with limited efficiency based on the resin contact area required for effective conversion. Utilizing a resin bead that is ¼ the size of traditional resin, Recoflo® Ion Exchange decreases the required reaction zone size significantly by taking advantage of the higher packaging density and surface area. This results in a much smaller system with higher operational efficiency and reduced waste.